When do we get to know each other?

Your visit with us:

Anyone coming to the Chiemgau for the first time will certainly not have been there for the last time. Whether as a travel group, in a club or with family, friends and colleagues: no visit to Traunstein would be perfect without stopping by our Hofbräuhaus Traunstein – ideally as part of a guided tour through our 400-year-old walls. Here you can experience with all your senses what moves us and with what passion we have been brewing for many generations. Our friendly hosts will be happy to share many interesting facts and stories as well as unforgettable impressions with you. Of course, you can also end the day with a tasting of our great beers and, if you like, a hearty snack in our cosy “Braustüberl”.

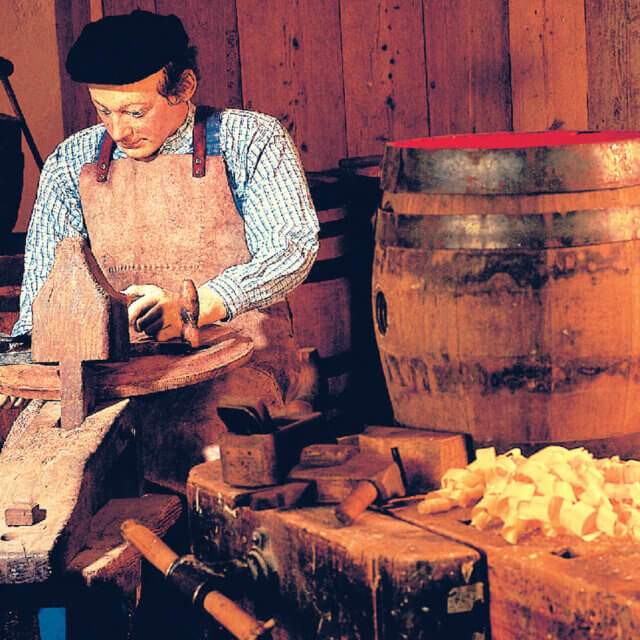

Brewery tour

With funny, interesting and historical stories we will guide you through the working brewery and show you our art of brewing. Live and in colour.

- Services: personal guided tour, small beer tasting with pretzel in our Maximilianstüberl

- Wednesday & Saturday at 11 a.m., Tuesday at 2 p.m. Monday & Thursday at 6 p.m., duration 2,5 hours

Flexible booking for groups and clubs - € 14,90 p.P.

€ 7,50 for children up to 16 years

Special tasting

With funny, interesting and historical stories we will guide you through the working brewery and show you our art of brewing. Live and in colour.

- Services: personal guided tour, beer tasting of 5 beers with pretzel in our Maximilianstüberl including beer connoisseur certificate.

- every 14 days

Duration 3 hours - € 34,90 p.P.

€ 17,50 for children up to 16 years

VIP master brewer tour

With funny, interesting and historical stories we will guide you through the working brewery on five stations and show you our art of brewing. Live and in colour.

- Services: personal guided tour, sensory beer tasting of 3 beers with our brewmaster and small snack in our Maximilianstüberl

- once a month

Duration 3,5 hours - € 49,90 p.P.

€ 24,50 for children up to 16 years

Questions and answers

Which Corona hygiene rules do I have to adhere to?

In accordance with current regulations, we impose distancing rules and masks as well as a limited number of participants.

Where can I park?

Parking is available at the Karl-Theodor-Parkplatz in Traunstein, approx. 10-minutes walking distance to the brewery. We recommend using the Parkster app for this.

Are there any discounts?

We offer discounts for children under 16 years of age as well as for groups, regulars’ tables, and clubs. Please contact us for details.

Can children come along?

Children are welcome to join us, however the guided walk is not accessible with a pushchair. Children would have to be carried or led by the hand. Pushchairs can be „parked“.

Are animals allowed?

No, animals are not allowed here.

Where can I eat?

In our Bräustüberl on Traunsteiner Stadtplatz there are hearty meals for afterwards.

Is the tour suitable for people with disabilities?

The tour goes through the brewery and is not barrier-free.

What should I wear?

We recommend flat shoes.

Where does the tour start?

The tour starts in the Hofbräuhaus Traunstein, Hofgasse 6, 83278 Traunstein. The meeting point is the Maximilianstüberl.